Press Release

World's First Development of Remote Cable Monitoring System Using Existing Underground Power Transmission Lines

August 18, 2020

Sumitomo Electric Industries, Ltd.

Sumitomo Electric Industries, Ltd. (Head Office: Chuo-ku, Osaka; President: Osamu Inoue; hereafter, "Sumitomo Electric") and TEPCO Power Grid, Inc. (Head Office: Chiyoda-ku, Tokyo; President: Yoshinori Kaneko; hereafter, "TEPCO PG") have jointly developed a remote monitoring system that readily uses existing underground power transmission lines to quickly build a sensor network for the first time in the world.

Power grid companies have power transmission line facilities installed in underground tunnels, pipelines and maintenance holes. These facilities are manually inspected and maintained by workers who are painstakingly descending into underground tunnels and maintenance holes, of which operating efficiency has been an issue. In the meantime, to secure stable supply, power grid companies are requested to install the latest technologies using IoT and AI to quickly detect equipment failures and diagnose facilities. However, building new communication infrastructure to operate and monitor the relevant remote sensors would require substantial investment.

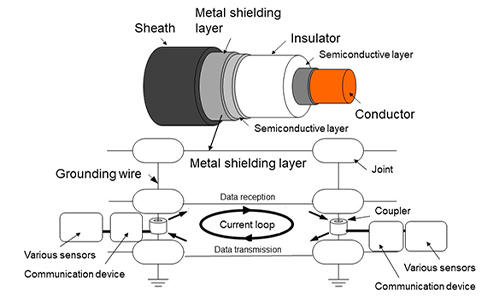

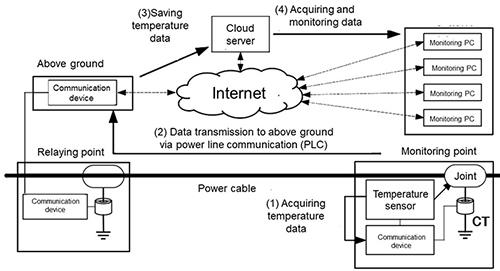

TEPCO PG and Sumitomo Electric have jointly developed and demonstrated a remote monitoring system (Fig. 2) that can easily build a sensor network based on power line communications (G3-PLC)*1 by using a metal layer, or a shielding layer, of an existing underground power transmission line of 66 KV or more as a new data transmission line (Fig. 1). In this system, a small split CT*2 is attached to the bond wire*3 installed at the connection in the middle and ends of the power transmission line, enabling power line communication using the existing shielding layer as the data transmission line. By using this system, the sensor data is transmitted to above ground and then to the cloud server for data storage by using existing above ground communications means, such as mobile line. The system can eliminate the need to lay a new data communication line, building a highly reliable sensor network at low cost. Sumitomo Electric has developed the system that uses the shield layer of an underground power transmission line as a data transmission line, and it has been verified and adopted by TEPCO PG since July this year to monitor the equipment temperature in the underground tunnels operated by the company.

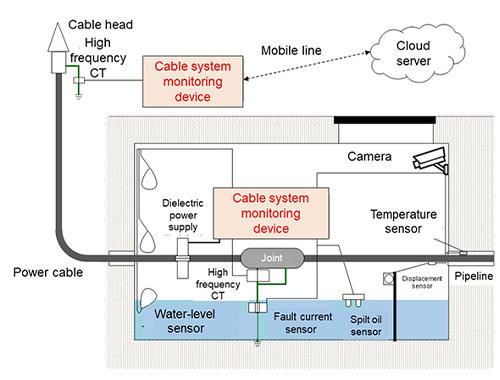

Currently, the two companies are developing a system that can acquire information*4 in maintenance hole facilities (Fig. 3), which has been difficult to acquire, aiming for practical use in 2021. Sumitomo Electric will continue advancing the sophistication of power line maintenance and contribute to solving the problems of labor shortages and stable power supply by developing a system that adopts Digital transformation using AI and IoT based on sensor data.

*1 This was achieved by utilizing the low frequency (about 150 to 400 kHz) used for smart meter data transmission.

*2 CT: Current transformer. Inductive coupling method that induces signals in the shielding layer without contact.

*3 Single line to the shielding layer to connect to the ground and the adjacent section

*4 Temperature, electric current, water level, images, etc. in maintenance holes