As a vertically integrated company, Keystone Powdered Metal Company can provide all processing in-house for the components we manufacture. This gives us a unique advantage over other powder metal suppliers that have to outsource secondary operations. Streamlining the process cuts lead time for manufacturing, minimizes risk of supply disruption, and provides the most cost competitive product for our customers. Below is more information on what we provide:

Keystone Powdered Metal Company is recognized as a top supplier for precision machined product with the most challenging specifications in the powdered metal industry.

For the majority of our product, multiple machining operations are required. KPMC utilizes one-piece flow work cells, completing all operations with automated inspection to provide the highest quality and most cost-effective solution to our customers. Of course, we also supply product that requires single operation processing. In these cases, we can offer automated handling of product and similar inspection capabilities in a simpler cell configuration.

Through our years of experience and excellent process controls, we can also offer IATF 16949 certified machining support for high-volume applications outside of our traditional PM process. We can support non-PM blank machining of steel, aluminum, stainless, and other material grades. Below is a list of automated CNC machining operations we provide:

Keystone Powdered Metal Company offers in-house batch and continuous heat treatment operations. This allows better quality control of our product and a more cost effective solution for our customers.

KPMC has 5 integral quench, batch furnaces for heat treatment of material. We provide normal batch tempering and also vacuum tempering for product with tighter cleanliness requirements.

2 automated induction hardeners for sprocket teeth and 2 units for localized hardening of components are installed at KPMC. This allows us to meet the challenging specifications for automotive components requiring this process.

KPMC has 2 batch steam treatment furnaces for surface oxide layer creation. This process can be used to improve corrosion and wear resistance, increase surface hardness, and seal porosities common with PM components.

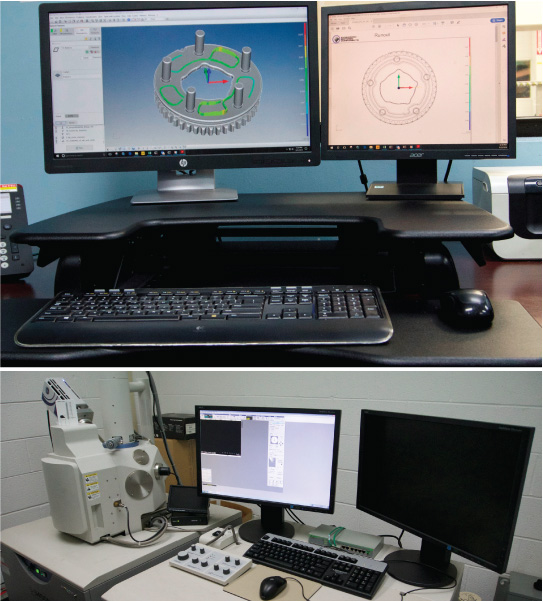

Keystone Powdered Metal Company has continued to advance our technology to support improved product quality through process control.

With the challenging specifications for the components we supply, gentle handling of material in process is a most important factor. By automating work cells, KPMC has taken most of the material handling out of the hands of humans, greatly reducing defect creation and inconsistency in methods.

KPMC embraces the principles of statistical process control. We have automatic data collection of in-process product measurement to give immediate feedback to operators of their process capability. This real-time analysis allows us to keep our process within calculated control ranges to avoid defect creation.

Our biggest competitive advantage comes from our experience and engineering capability. We work closely with our customers to determine possible defect concerns and create systems to protect flow out to them or their customer. We have the best technology and in-house expertise to engineer these solutions prior to production launch.

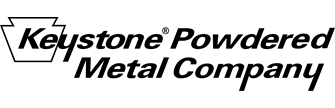

Keystone Powdered Metal Company has state-of-the-art metrology available for on-site confirmation of quality criteria adherence. From incoming material inspection, measurements through each process, and final validation of product for shipment, our quality control personnel ensure we are satisfying our customers' expectations.

In addition to basic laboratory gauges and equipment, KPMC also has the following specialized measurement systems: