Products

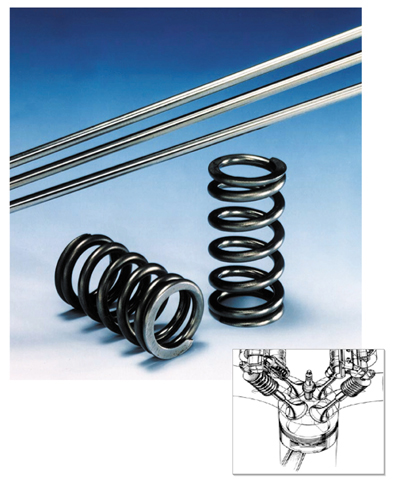

Oil Tempered Wire

The production process of oil tempered wire consists of drawing, heating to above autenitizing temperature and quenching into oil or equivalent quenchant, so that fine tempered martensite having high fatigue strength and enough ductility is obtained.

Our oil tempered is using super clean steel to minimize the risk due to non metallic inclusion. Since the state of the art technologies and well established quality management system are applied, our oil tempered wire shows outstanding performance and has good reputations among global customers.

Chemical Compositions

| Wire Grade | Diameter range (mm) |

Chemical Compositions | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | V | Co | ||

| SWOSC-V | 0.5-9.2 | 0.51- 0.59 |

1.20- 1.60 |

0.50- 0.80 |

-0.025 | -0.025 | 0.50- 0.80 |

- | - |

| SWOSC-VH | 0.8-9.2 | 0.63- 0.68 |

1.30- 1.60 |

0.60- 0.80 |

-0.025 | -0.025 | 0.50- 0.80 |

- | - |

| SWOSC-VHV | 0.8-9.2 | 0.63- 0.68 |

1.20- 1.60 |

0.50- 0.80 |

-0.025 | -0.025 | 0.50- 0.80 |

0.10- 0.20 |

- |

| SWOSC-VHS | 0.8-6.5 | 0.63- 0.68 |

1.80- 2.20 |

0.70- 0.90 |

-0.025 | -0.025 | 0.50- 0.80 |

0.05- 0.15 |

- |

| SWOSC-VHR | 2.5-5.0 | 0.63- 0.68 |

2.10- 2.30 |

0.50- 0.70 |

-0.025 | -0.025 | 1.10- 1.30 |

0.10- 0.20 |

0.10- 0.30 |

Mechanical Properties

| Nominal Dia 1) (mm) |

Tensile Strength (N/mm²) |

Tolerance (mm) |

Ovality (mm) |

||||

|---|---|---|---|---|---|---|---|

| SWOSC-V | SWOSC-VH | SWOSC-VHV | SWOSC-VHS | SWOSC-VHR | |||

| 2.0 | 1910- 2060 |

2110- 2210 |

2110- 2210 |

2160- 2260 |

2210- 2310 |

±0.02 | 0.02 |

| 3.0 | 1860- 2010 |

2060- 2160 |

2060- 2160 |

2110- 2210 |

2160- 2260 |

±0.02 | 0.02 |

| 4.0 | 1810- 1960 |

2010- 2110 |

2010- 2110 |

2060- 2160 |

2110- 2210 |

±0.03 | 0.03 |

| 5.0 | 1760- 1910 |

1960- 2060 |

1960- 2060 |

2010- 2110 |

2060- 2160 |

±0.03 | 0.03 |

Double Eddy Current Test

For 2.1~6.0mm in diameter, double eddy current tests, i.e. stationary and rotating types, are applicable.

Packing

| Wire Diameter (mm) |

Coil Size(mm) | Coil Weight(kg) | ||

|---|---|---|---|---|

| Inner Diameter | Outer Diameter | Lapped Coil | Coil with Carrier | |

| 0.5-1.2 | 250 | 550 | 50 | 100 |

| 1.3-1.9 | 600 | 900 | 100/200 | 400 |

| 2.0-2.9 | 600 | 900 | 100/200 | 400 |

| 1000 | 1400 | 200/400 | 800 | |

| 3.0-5.2 | 1000 | 1400 | 200/400 | 800 |

| 5.3-13.0 | 1300 | 1650 | 200/400 | 800 |

Technical Note

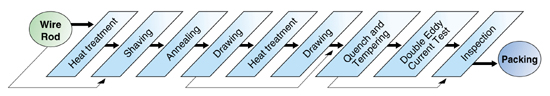

(1)Manufacturing Process

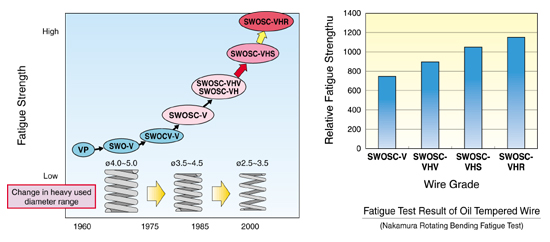

(2)Fatigue Strength

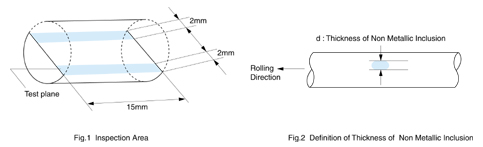

(3)Microscopic Test of Non-Metallic Inclusions (Max.T Method)

The samples are taken in wire rod state and those longitudinal sections are polished. For each sample, both the top and bottom surface zones that are from the surface to 2mm inside and having 15mm length shall be inspected (i.e. 60mm² area, see fig.1). For each heat, 10 samples shall be inspected and maximum thickness of observed non- metallic inclusions (see fig.2) shall not be over 15µm or larger.

Instructions

Since Oil tempered wire is susceptible to hydrogen brittleness and delayed fracture, please observe the following instructions.

- Tempering shall be applied immediately after coiling.

- Pickling nor plating shall not be applied.

- The wire shall not be used under corrosive environment.