Celmet™

Aluminum Celmet™

Teralink™

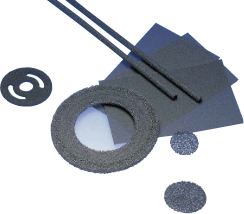

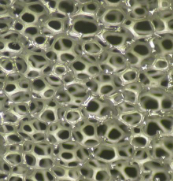

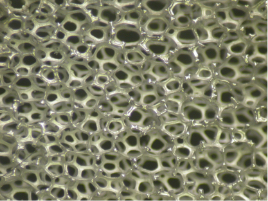

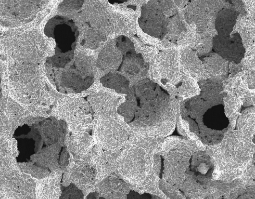

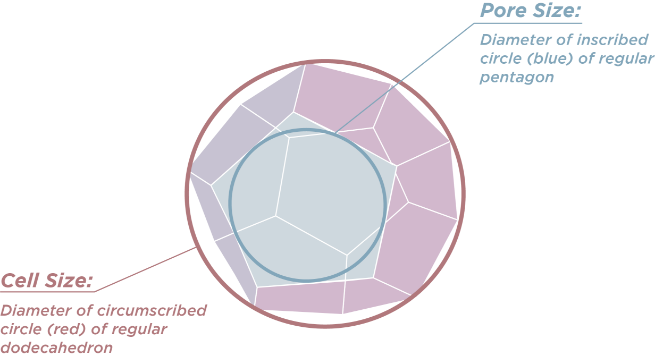

Celmet is a unique porous metal in which triangular-prism-shaped cells are interconnected to form a three-dimensional structure. Celmet has a maximum porosity of 98%, large surface area, and has high conductivity. The porosity is significantly higher than that of porous materials derived from sintered metal powder or metal grains.

Available porous metal materials include nickel (Ni) and alloy types of nickel-chrome (Ni-Cr), nickel-tin (Ni-Sn), aluminum* (Al), and copper* (Cu).

Applications of Celmet include—but are not limited to—catalyst carriers, photocatalyst carriers, heat applications (in electronics, building materials, servers, and vehicles), grease filters, electrodes for alkali water electrolysis, and fuel cells (solid oxide fuel cells (SOFC), polymer electrolyte fuel cells (PEFC)).

Celmet is widely used in various industrial fields and is expected to be applied to new fields, such as the structural parts of fuel cells for stationary and automotive uses, and as electrodes for hydrogen generators.

* Under development.

Nickel alloy Celmet can contribute to the realization of a hydrogen society. It has the potential to improve efficiency in hydrogen generation and to reduce the cost of electricity from fuel cells. This is due to its high porosity, high surface area, excellent conductivity, high thermal resistance, and high corrosion resistance.

Features

Applications

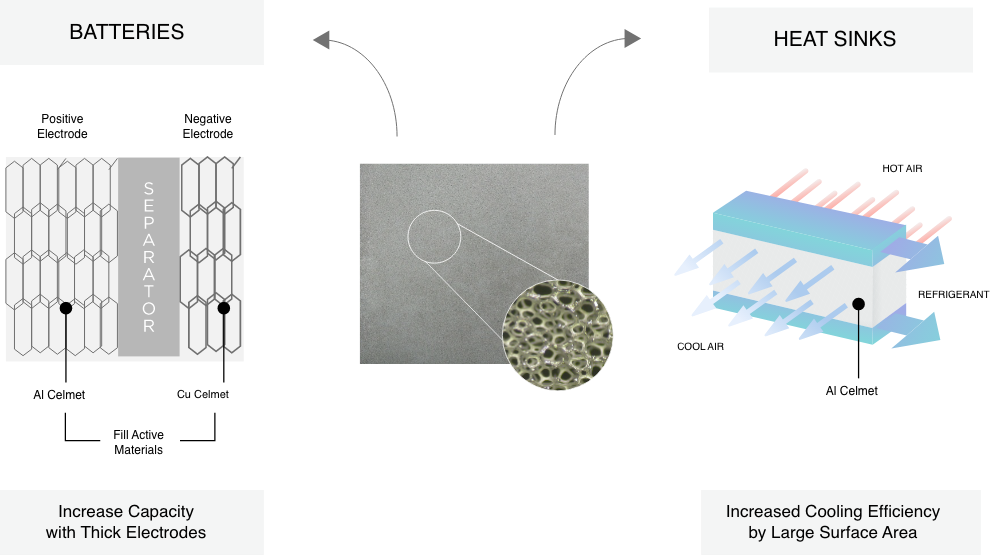

Aluminum Celmet is a unique material. With characteristics like nickel Celmet, Al Celmet is lightweight and has excellent heat conductivity and high porosity.

Features

Applications

98% Porosity Metal

Celmet consists of a porous metal body whose frame has a three-dimensional network structure similar to sponge. We are currently mass producing technologies for Ni (nickel) Celmet, and are providing this product to the automotive industry.

At this time, Sumitomo Electric has succeeded in developing Al (aluminum) Celmet. Characteristics include higher porosity of a maximum of 98%, light weight, high electrical conductivity, and greater surface area compared to sintered metal and metal fiber. Al Celmet can be used for various applications such as aerospace, automotive, energy fields, and much more.

Features

Specifications

| Porosity | 95% |

| Cell number | 46 - 50 pcs/inch |

| Cell diameter | 0.5 mm |

| Surface area | 5,000 m²/m³ |

| Thickness | 1.0 mm |

| Weight | 140 g/m² |

| Breaking strength* | 0.5 MPa |

| Resistance* | 3 μΩ · m |

* Measured with 10 mm width

Lineup

| 140 | 1.0 | 46 | 550 | 95 |

| 100 | 1.0 | 46 | 550 | 96 |

| 200 | 2.0 | 30 | 850 | 96 |

Applications

For more information:

Contact UsA thermoplastic polymer that is cross-linked by Sumitomo Electric's unique electron-beam irradiation technology. This technology not only delivers a polymer that has higher strength at temperatures above Tg, but also better wear and fatigue resistance.

Features

Applications

Use Teralink to optimize your design by reducing weight, size, cost, etc.