Home > POREFLON > Development History

The history leading to the development of the innovative POREFLON water treatment stretches back over 50 years.

This is the story of how Sumitomo Electrics knowledge and passion came together to help solve the world’s water problems.

- POREFLON, a proprietary material with a 50-year history

- POREFLON is an innovative porous material manufactured by Sumitomo Electric from 100% polytetrafluoroethylene (PTFE) with first patent on its PTFE expanding technology in 1962. POREFLON has four important features. Excellent chemical resistance to acids, alkalis and solvents surpass that of polyvinylidene difluoride (PVDF) or polyethylene (PE). Robustness allowing prolonged period of use. The highest porosity among competitive membranes and high water permeability. And heat resistance that allows membrane filtration even at up to 200°C.

These properties make POREFLON perfect at first for flat membrane products for chemical analysis and reagent applications, as well as high-purity chemical solution applications for the semiconductor and liquid crystal industries. It is also used for special applications such as electric wire coating and artificial blood vessels.

- Water is a key to the future of POREFLON!

- A report in a technical journal about water treatment using a polyethylene membrane module mentioned the challenges presented by the strength and chemical resistance of the membrane module. Water shortages and pollution were clear environmental issues, demonstrating demand for products made with PTFE. After completing a prototype, engineers worked with water treatment system builders for field testing. However, the results were not favorable, as it clogged faster and had a lower flow rate than conventional products.

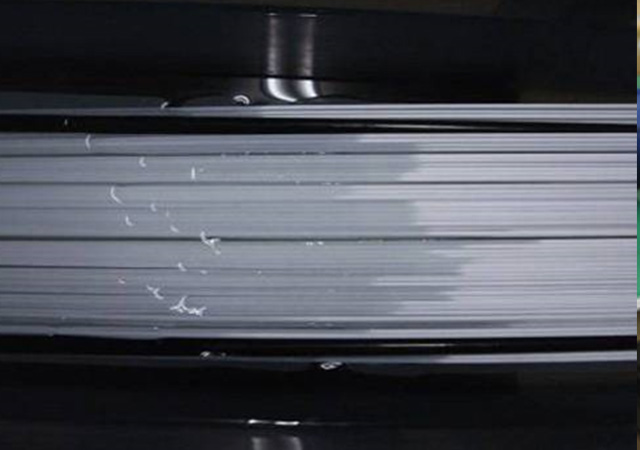

Immediately, work began on a new prototype. The new prototype employed a composite structure with a hollow fiber membrane with large pores and good permeability wrapped with an ultrathin layer with small pores. The outer membrane had a pore size of 0.1 μm, while the inner membrane pores were 2μm, for an overall porosity of 80%. This PTFE composite hollow fiber membrane offered both high strength and flow rate. Successive improvements increased the flow rate nearly four-fold while decreasing the cost to one-fourth that of previous products.

Development of this technology was possible thanks to the expertise of Sumitomo Electric as an electric wire manufacturer. Electric wires consist of an inner metal wire and an outer insulation coating, similar to the structure of the PTFE composite hollow fiber membrane. To create a prototype based on the new concept, the development team could learn from the electric wire division. In addition, equipment was borrowed and manufactured in-house, laying the path to mass-production technology.

- POREFLON used in major construction in Korea

- After progress was made on the water treatment technology, the team was visited by a Korean businessman who was interested in selling POREFLON sheets for clothing. The development members, instead, encouraged him to market the water treatment technology currently under development. He accepted their proposal and started marketing in Korea.

Travelling across the country, he visited sewage treatment plants with samples of membrane modules packed in his car. Sewage treatment had become a national concern in Korea, so the response was unexpectedly positive. Water treatment system builders at that time were also developing technology and testing modules from competitors, but they could not meet the performance requirements. This paved the way for POREFLON water treatment modules to make their debut. When Daewoo E&T, a major Korean construction company, decided to incorporate Sumitomo Electric's POREFLON water treatment membrane module in several sewage treatment plants to be built in Sinpyeong, it was clear that POREFLON’s time had arrived.

- Putting theory into practice

- The water treatment modules for the Sinpyeong sewage treatment plant needed to handle a daily sewage of about 10,000 m³, a totally different scale than the prototypes. There were many challenges in creating an actual commercial system, including optimizing alongside sewage treatment methods using microorganisms. Initially, the flow rate of the modules did not reach the targets, not because of the performance of the hollow fiber membrane for water treatment, but instead due to the overall assembly structure. A manual trial and error approach was used to find out the optimal structure.

One major challenge was the need to use real wastewater for evaluation of the system. Membrane samples were repeatedly created in Japan and transported to Korea for testing, and then brought back to Japan for analysis. All of this hard work led to the successful development of POREFLON membrane modules for a large-scale commercial plant.

POREFLON established a new standard in water treatment technology.

This technology is now being used everywhere from

water treatment modules to next-generation one-stop solutions.

Sumitomo Electric continues to challenge itself to solve the world's water problems.