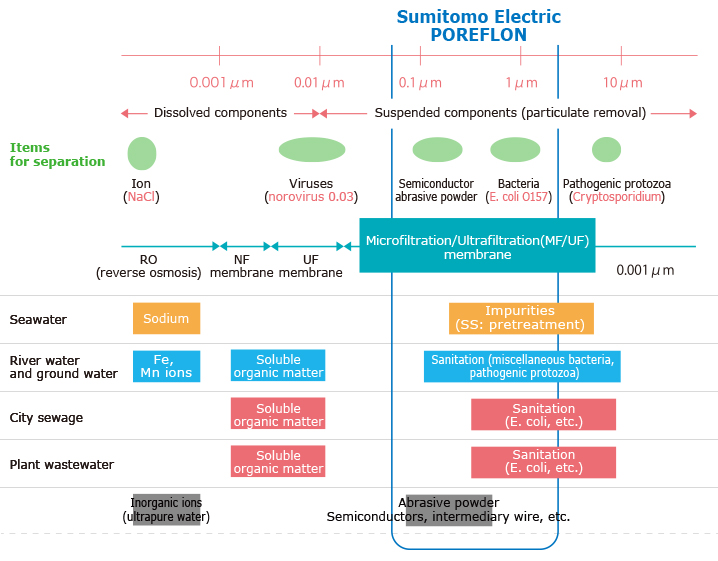

POREFLON

POREFLON Membrane Modules are durable high-quality membranes that have chemical and thermal resistance.

These modules are reasonably priced and easy to handle.

POREFLON Membrane Module

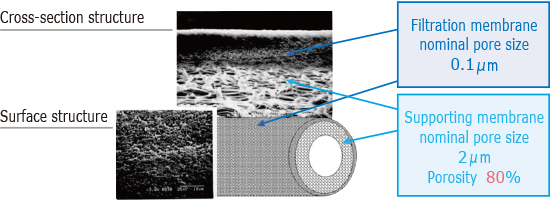

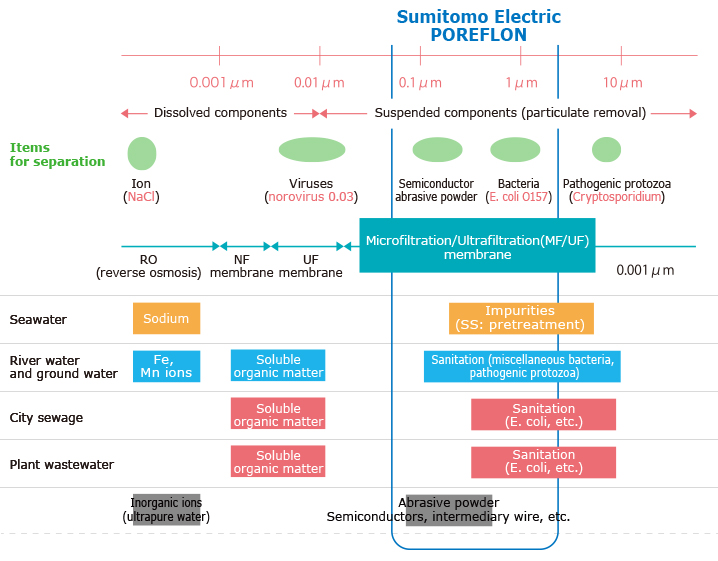

The POREFLON hollow fibers used as the filtration membrane have a composite structure, with a dense filtration layer on the outside and a supporting structure on the inside. This double structure offers the filtration accuracy by the outer layer, while the inner layer provides strength and durability. This structure enables advances water treatment capability for a variety of applications.

Features of POREFLON Membrane Module

-

- Chemical resistance

(Flow recovery) - The module can be cleaned with various chemicals from pH 0 to 14 including high-concentration alkalis, with excellent flow recovery.

DATA 1

- Chemical resistance

-

- Thermal resistance

- Membrane filtration applications are possible at temperatures up to 200°C (392°F). It is also suitable for treating oil-contaminated wastewater.

-

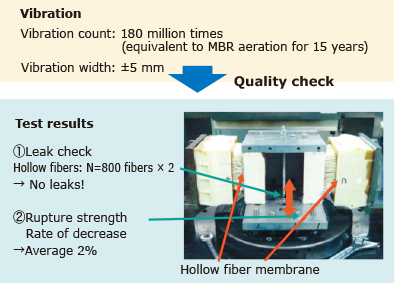

- Durability

- The hollow fiber membrane with high tensile strength is durable against shaking and flexing, and can be used for an extended period of time.

DATA 1 DATA 2

-

- Permeability

- The high porosity ensures high permeability and offers excellent water treatment capability.

DATA 1

-

- Energy saving

- The proprietary aeration system offers efficient air scouring for membranes.

-

- Easy handling

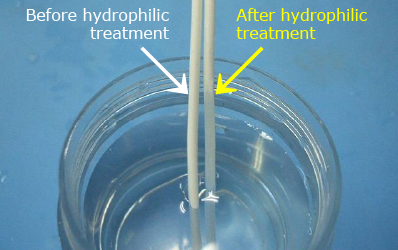

- The PTFE hollow fibers are treated to be hydrophilic enabling ease of transportation and installation in a dry condition.

DATA 1

-

- Oil resistance

- The membrane is less prone to clogging, and can be cleaned with harsh alkalis, allowing treatment of oil-contaminated.

DATA 1 DATA 2

![]()

- Chemical resistance (Flow recovery) DATA1

- The POREFLON Membrane Module is resistant to nearly all chemicals. The hollow fiber membrane can be washed with high-concentrated acids and alkalis. This means the membrane offers longer service life. In particular, the membrane has excellent resistance to high-concentrated alkali, making it usable for oil-contaminated wastewater treatment that has not gone through membrane filtration and wastewater from semiconductor and solar battery manufacturer that includes silicone.

![]()

- Durability DATA1

- The hollow fiber used in the POREFLON Membrane Module is highly durable against shaking and flexing, and it can operate without membrane breakage during air scouring.

![]()

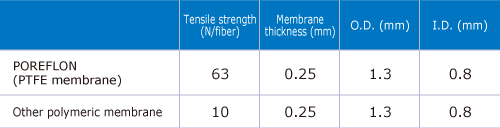

- Durability DATA2

- The hollow fiber used in the POREFLON Membrane Module has a tensile strength that is six to ten times higher than hollow fiber membranes made of other materials, therefore, it would not be torn off during an extended period of operation.

![]()

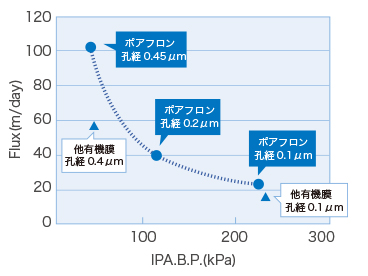

- Water permeability DATA1

- The membrane has a high porosity of between 75% and 85% to control resistance during transmission for high water permeability performance. In addition, the PTFE structure with two layers, a skin (filtration) membrane and supporting membrane, ensures excellent fouling resistance.

![]()

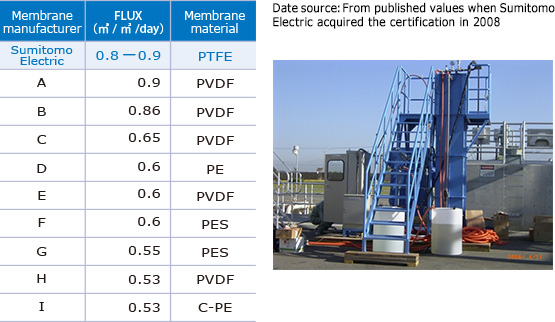

- Permeability DATA1

- The POREFLON Membrane Module has high permeability with an A rank, and the high porosity enables high permeability, which in turn helps realize excellent permeability. This technology is used in sewage treatment and industrial wastewater treatment.

![]()

- Operational ease DATA1

- Hydrophilic polymer is cross linked to PTFE fibers enabling long lasting hydrophilicity. It enables transport while dry. The module does not need to be hydrophilic treated at the site. The hydrophilicity remains even when stored dry after use, so the module can immediately pass through water when run again.

![]()

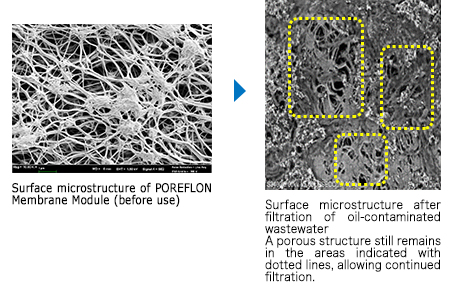

- Oil-contaminated wastewater treatment capacity DATA1

- Three-dimensional fibril structure and high porosity of PTFE hollow fiber membrane prevent oil clogging. In addition, the membrane is highly resistant to alkali, which is essential in removing oil deposits. Although oil-contaminated wastewater had been difficult to treat with a membrane in the past, POREFLON is less prone to clogging and can be cleaned with alkali.

![]()

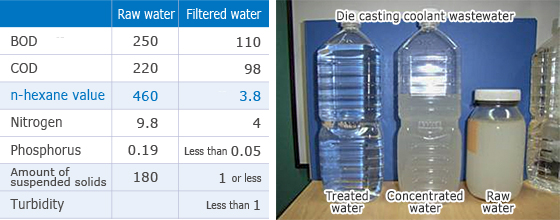

- Oil-contaminated wastewater treatment capacity DATA2

- The table below shows that the membrane was able to reduce the oil concentration in the wastewater from 460mg/L to 3.8mg/L, less than 1/100th the original concentration. The POREFLON Membrane Module is highly regarded for its effectiveness in removing oil, and it is being used to treat produced water in the oil field, wastewater from oil refineries, petrochemical plants and cold rolling in steelworks.

Module Lineup

- Stable flux

- The PTFE membrane combines highly durable hydrophilicity with asymmetric structure (double structure) to achieve excellent fouling resistance.

- Compatible with a wide range of wastewater

- Stable treatment can be achieved even for wastewater that contains oil and refractory organic matters. The PTFE membrane allows cleaning with strong alkali cleaning agents.

- Low operating costs and space saving

- The proprietary aeration system offers efficient air scouring for membranes with less aeration energy. In addition, the large membrane surface area per projection area greatly reduces the installation space.

- Large volume water treatment

- This system is ideal for applications of a large volume of flow with relatively low turbidity.

*General industrial wastewater treatment, oil-contaminated wastewater, water purification (ground water, surface water, etc.)