- For Connectors

-

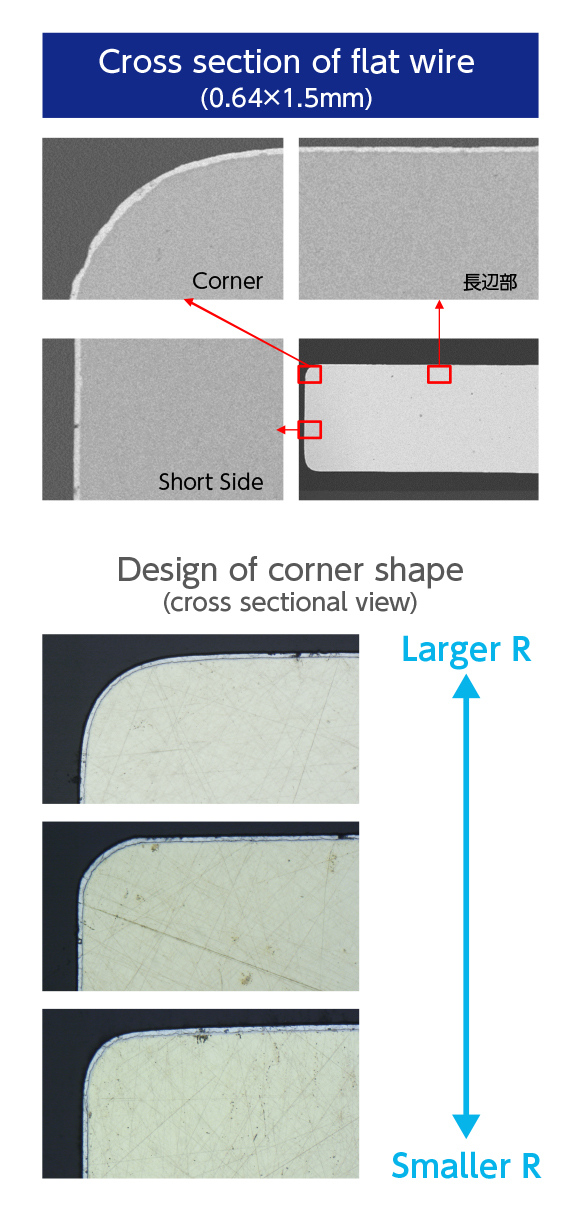

- Flat wires with high oblateness (0.64 x 1.5mm, 0.64 x 2.3mm) are available.

- Plating on the entire wires surface (uniform plating on corners) are available.- Smooth finish by die machining facilitates soldering for skin pass surface and ensures uniformity of plating to the edges of rectangular wires.

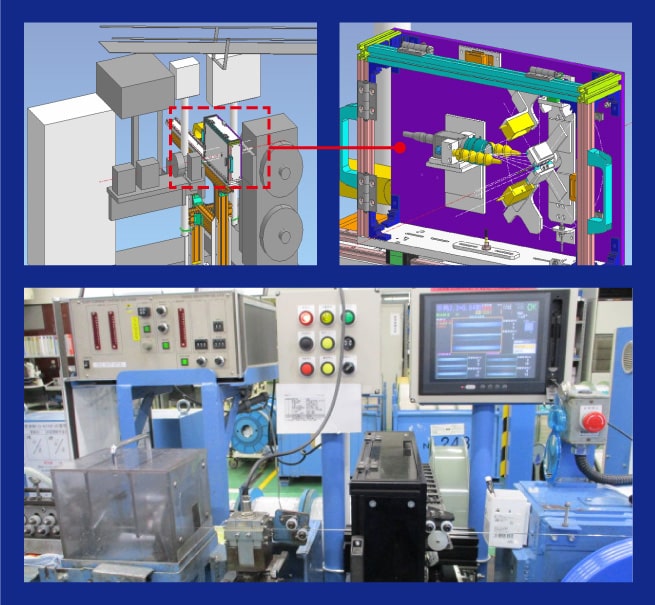

- High Plating Quality Assurance by Imaging Sensor and Flaw Detector

- - Sumitomo Electric's electroplated wires are employed in the automotive industry that requires high level of quality control.

- Camera Inspection