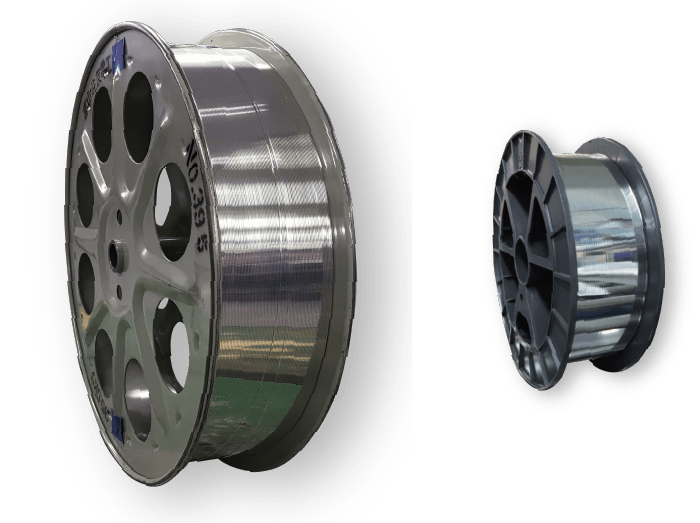

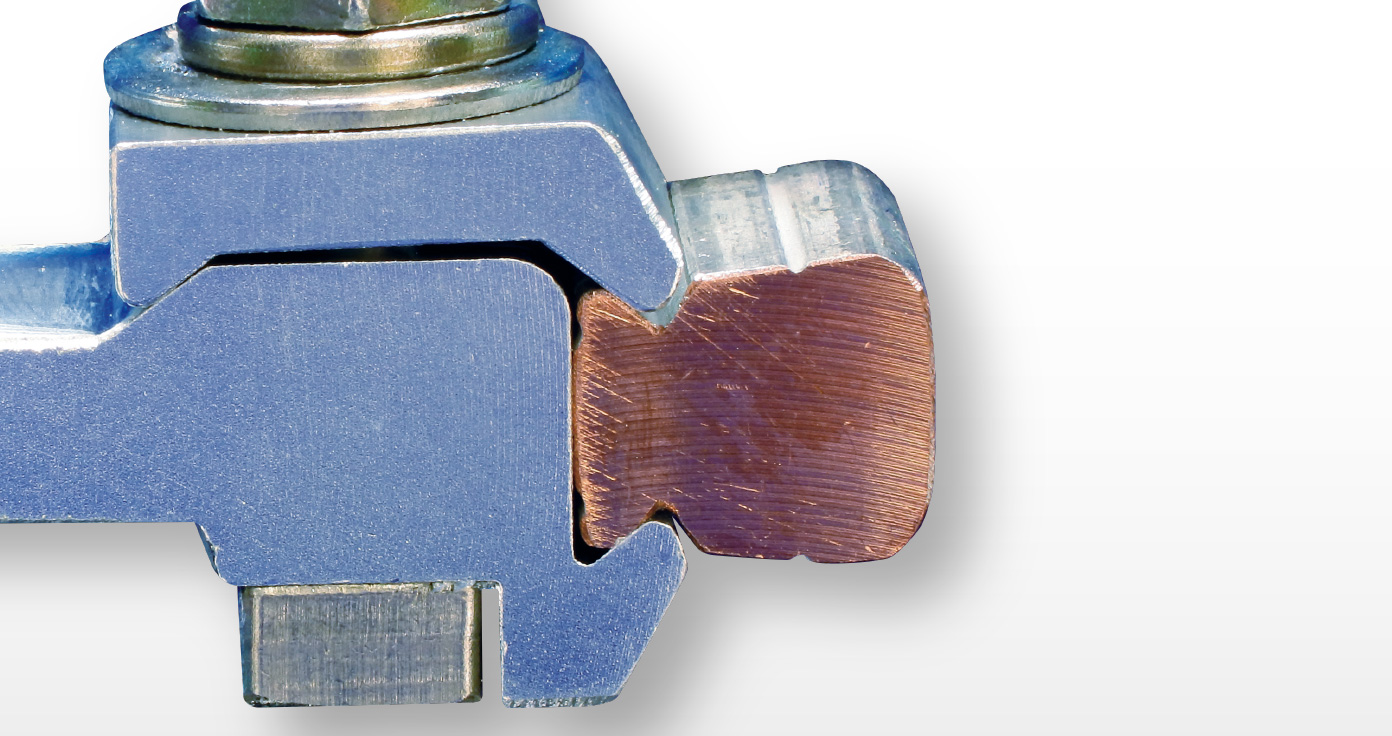

- Reflow Tin Plated Wire

- Sumitomo Electric's continuous,

lead-free electroplating line is capable of

plating on various cross-sectional shapes

as well as copper- or nickel- under plating.

- Reflow Tin Plated Wire and

Tin Plated Flat Wire - Sumitomo Electric manufactures products of high quality

and relilability with uniform plating thickness

and shapes even on flat wire.