Technical Information

Applications and Characteristics

| Function | Applications | Material |

| Catalyst carrier |

|

Ni, Ni-Cr, Ni-Sn |

| Filtering |

|

Ni, Ni-Cr, Ni-Sn |

| High conductivity |

|

Ni, Ni-Cr, Ni-Sn |

| Electromagnetic shielding |

|

Ni |

※You can check this table by side scrolling.

Application

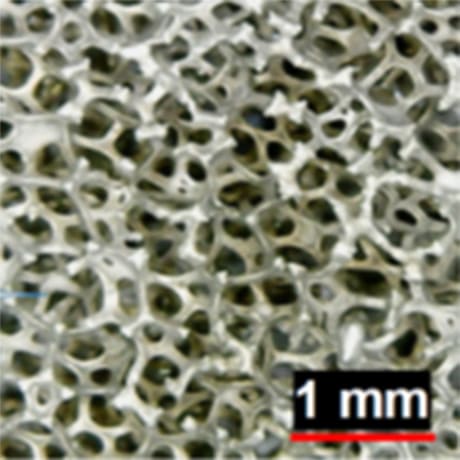

1Catalyst Carrier

Celmet™ has been adopted as industrial deodorizing catalyst.

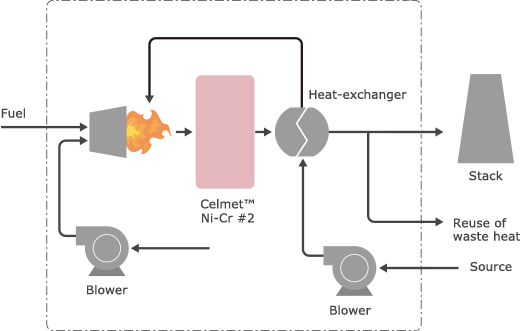

Industrial Deodorizing Catalyst

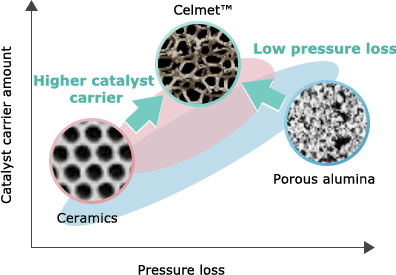

Comparison of catalyst carrier

| Ceramics | Porous alumina | Celmet™ | |

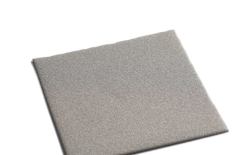

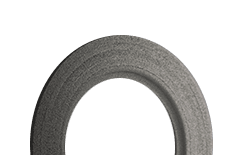

| Appearance |  |

|

|

|---|---|---|---|

| Pressure loss | ◎small | △large | ○middle |

| Amount of catalyst carrier | △small | ◎large | ○middle |

| Mechanical strength | △weak | ○middle | ◎strong |

Catalyst carrier

Advantages of applying Celmet™

Improve performance

- Compared to ceramics, the amount of catalyst carrier is increased due to its large surface area.

Low pressure loss

- Compared to porous alumina, Celmet™ demonstrates a better balance between low pressure loss and high catalyst carrier.

Durability and strength

- Compared to ceramic filter, Celmet™ is durable and can be used repeatedly.

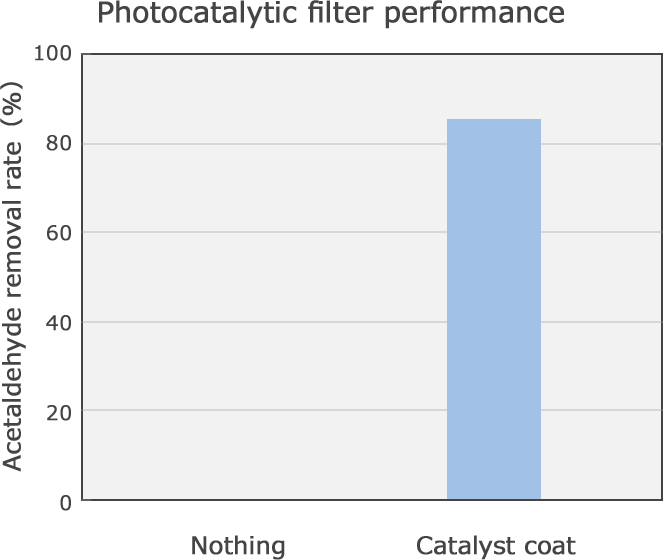

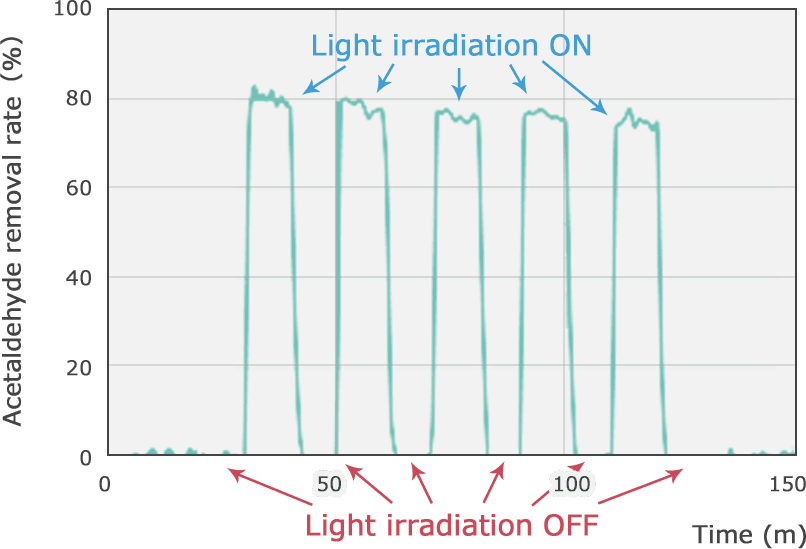

2Photocatalyst Carrier

Celmet™ can work as air cleaner filter.

High filter performance of 80% or more

Quickly respond to ON/OFF light irradiation

Measured under collaborative research with Kanagawa Institute of industrial Science and Technology (JIS R 1701-2:2016 Fine Ceramics - evaluation for air purification performance of photocatalytic materials, Part 2: photocatalytic performance evaluation based on removal performance of acetaldehyde)

Ni Celmet™

(Nothing)

Photocatalyst Ni Celmet™

(TiO2 coat)

Advantages of applying Celmet™

Performance improvement

- Removal rate of toxic substance is improved due to its large surface area of Celmet™

- Quickly respond to light irradiation

Durability and strength

- Celmet™ as a metal has impact resistance and durability

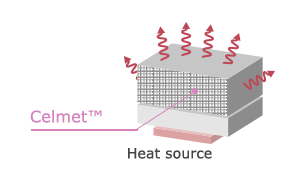

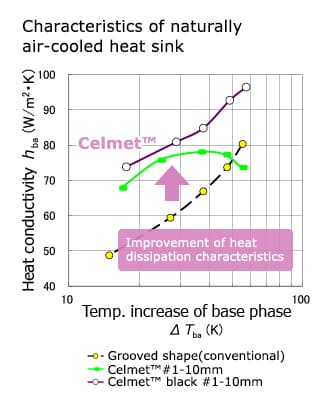

3Heat Applications

Celmet™ has been considered as naturally air-cooled heat sink for automotive.

Naturally air-cooled heat sink

Principle

Cooling by heat conduction to the air

Advantages

- Large surface area improves heat transfer efficiency

Applications

Electronics

Heat storage sheet

Principle

Cooling by phase-change latent heat of heat-storage material

Advantages

- Thickened heat storage sheet (improvement of storage material heat retention)

- Improved input and output speed of heat to heat-storage material。

Applications

Building materials, electronics

Advantages of applying Celmet™

High performance

- Miniaturization by improved cooling performance

Materials

- Ni

Application

- Naturally air-cooled heat sink

- Heat storage sheet (filling the heat-storage material)

- ebullient cooling (the starting point of boiling)

- electrical heating (Ni-Cr)

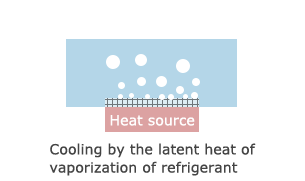

Heat source

Principle

Cooling by the latent heat of vaporization of refrigerant

Advantages

- Large specific surface area increases the starting point of boiling (improvement of cooling performance)

Applications

Server, supercomputer

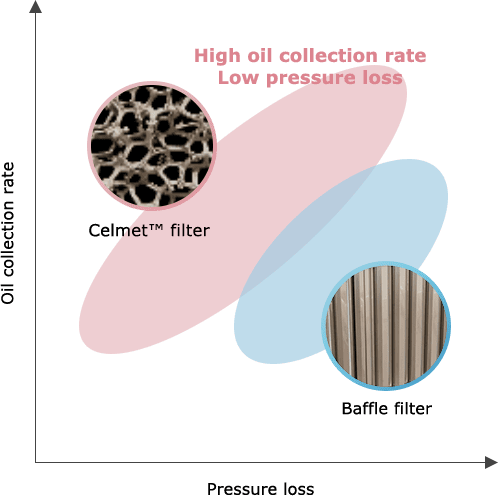

4Grease Filter

Celmet™ has been adopted in restaurants and commercial facilities.

Grease Filter Performance

Advantages of applying Celmet™

Collection performance

- Compared to baffle filter, Celmet™ has higher collection performance due to its large surface area.

Recyclability

- The material (nickel) can be repeatedly used by alkaline washing.

Strength and safety

- Compared to metal fiber or ceramic, Celmet™ has less chipping and mechanical degradation, improving safety.

- Compared to stainless steel baffle filter, Celmet™ has better fireproof performance due to lower thermal conductivity.

Weight saving

- The weight is one-third of baffle filter.

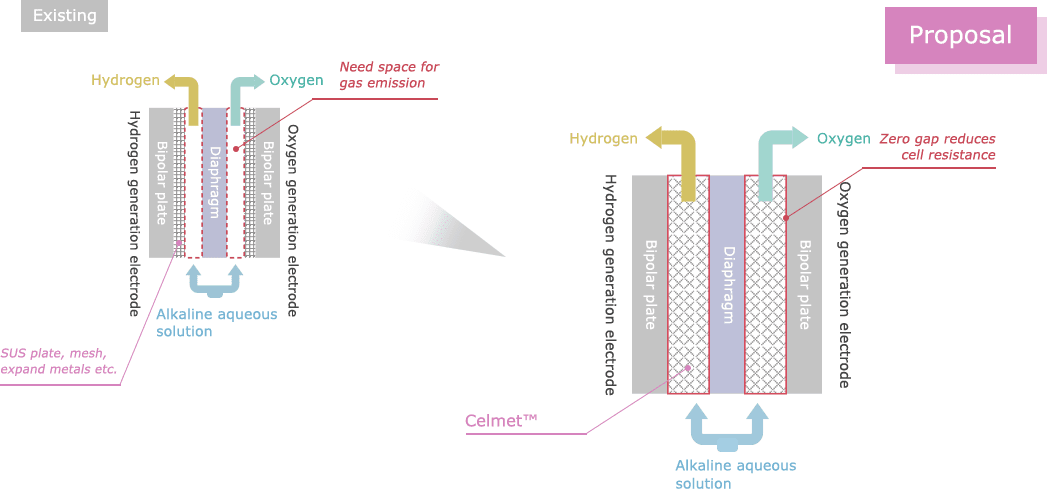

5Electrodes of Alkali Water Electrolysis

Celmet™ has been considered as industrial hydrogen generator.

Current-voltage characteristics of

hydrogen generation electrode

Celmet™ increases the amount of hydrogen generation

Advantages of applying Celmet™

Voltage reduction of alkaline water electrode cell

- Celmet™ is porous metal so that a zero-gap structure is possible and can reduce resistance of solution.

Improvement of hydrogen generation efficiency

- Compared to lath or mesh, applying Celmet™ to hydrogen electrode can increase the amount of hydrogen without increasing the cell voltage due to its large surface area.

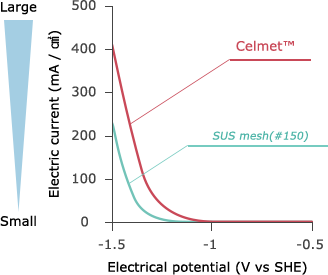

6Fuel Cells (SOFC)

Celmet™ has been adopted as current collector and

gas flow path of industrial and institutional fuel cells.

Proposal

SOFC Performance of Various Anode Materials

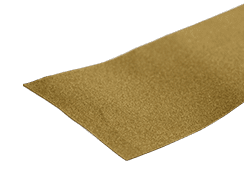

| Ni felt | Ni mesh | Ni Celmet™ | |

| Appearance |  |

|

|

|---|---|---|---|

| High fuel utilization | ○ high | × low | ○ high |

| Pressure loss | × big | △ middle | ○ small |

| Cell fracture | ○ few | × many | ○ few |

Advantages of applying Celmet™

low cost stack

- No need for complex gas flow.

compact stack

- Celmet™ can make interconnector thinner so that Celmet™ functions as gas flow path and gas diffusion.

reduction of pressure loss

- High porosity can reduce pressure loss.

Improvement of the fuel availability

- Celmet™ can improve the fuel availability because fuel gas flows uniformly.

Improvement of current collection performance of air electrode

- Ni alloy Celmet™ can be applied as air electrode, because it has good oxidation resistance.

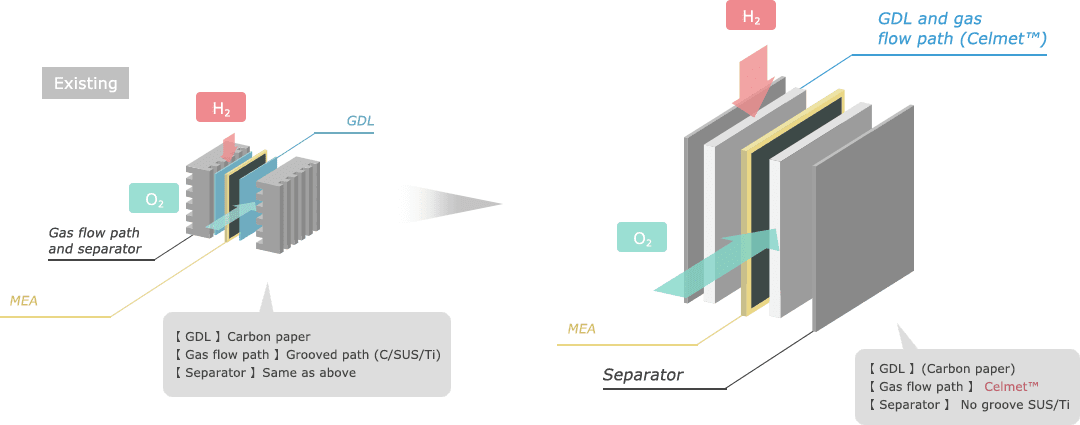

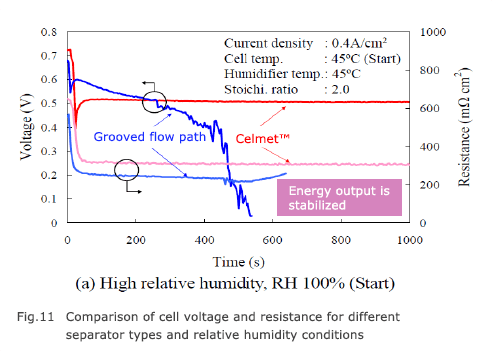

7Fuel Cells (PEFC)

Celmet™ has been adopted as current collector

and gas flow path of fuel cells for lift trucks.

Proposal

Energy Output Characteristics*

* TABE, NASU, MORIOKA and CHIKAHISA, 2012,

Analysis of Performance Characteristics and Internal Phenomena of PEFC with Porous Flow Field,Transactions of the Japan Society of Mechanical Engineers, Vol.78, No789, 204-212.

Advantages of applying Celmet™

Low cost

- No need for GDL and separators with complex gas flow path, and lower pressure loss.

Compact

- Celmet™ functions as gas flow path, gas diffusion and current collector.

Performance improvement

- Lower resistance and high-strength compared to carbon paper.

Higher energy output

- Higher current collection performance and improved flooding resistance – drainage is improved by capillary of Celmet™.

SEI TECHNICAL REVIEW

Application of Ni Porous Metal (Celmet™)

Application of Ni Porous Metal (Celmet™)

to Solid Oxide Fuel Cells ( 1.58MB ) Development of High Corrosion Resistance Celmet™ ( 262KB )

Development of High Corrosion Resistance Celmet™ ( 262KB )

Properties

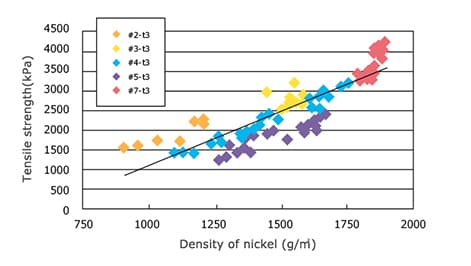

Tensile Strength (Nickel Celmet™)

Tensile strength is proportional to the nickel density regardless of cell size.

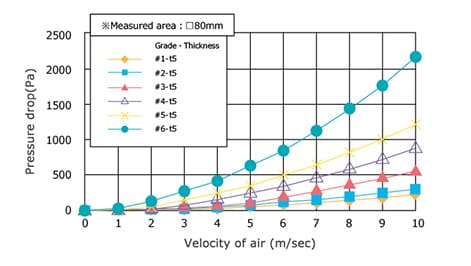

Pressure Drop (Nickel Celmet™)

By choosing part number and thickness, you can optimize the pressure loss.

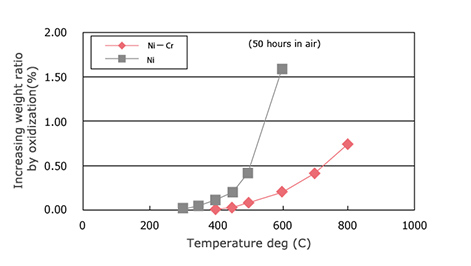

Heat Resistance (Oxidization)

Operating temperature limit:

Ni: 450-500 deg., Ni-Cr: 650-700 deg.

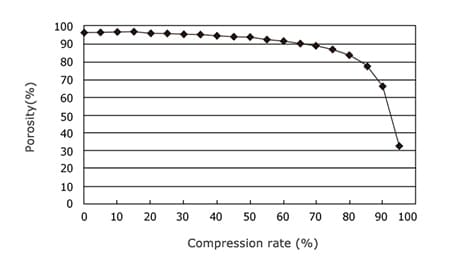

Relationship between Porosity and Compression Rate

Even when pressed down to half the thickness, the porosity is kept at 90%.

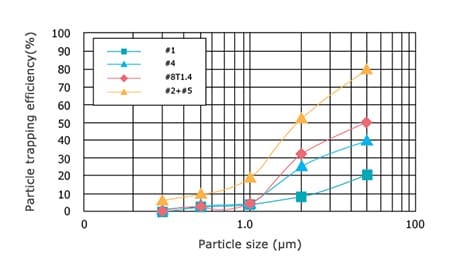

Dust collection Property

Grade#8-1.4mmt (pore size about 230µm) can trap 5µm particles at 50% rate.

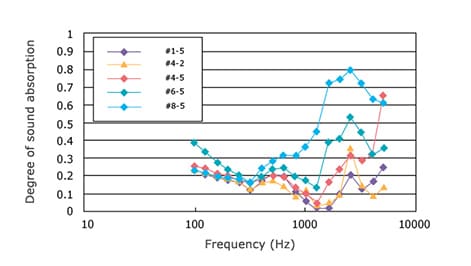

Sound Absorption (back air layer 300mm)

In the region of 3,000~5,000Hz, Celmet™ has good sound-absorbing properties.