HOME | Topics | Submarine Cable

In 1921, Sumitomo Electric manufactured and supplied the first high voltage submarine cable in Japan, the world's longest cable system at that time. We have supplied over 6,000*km of submarine cables in the past 100 years.

*As of Aug, 2020

Submarine cable is a vital component of offshore renewable energy (RE) projects such as wind farms. While submarine cables are sometimes installed in harsh environments that include currents, water pressure, high waves, or unforeseeable obstacles on sea beds. The installation of submarine cables requires much sophisticated technologies.

As one of the pioneers of the global submarine cable business, we Sumitomo Electric determines to deliver the world the comprehensive solution of design, production, installation and project management, for precisely and timely execution of complex installation projects.

In order to obtain long-life cable performances, in general submarine cables shall have:

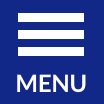

Cross Section of General 3-Core Submarine Cable

Cross Section of General 3-Core Submarine Cable

1-Core Submarine Cable

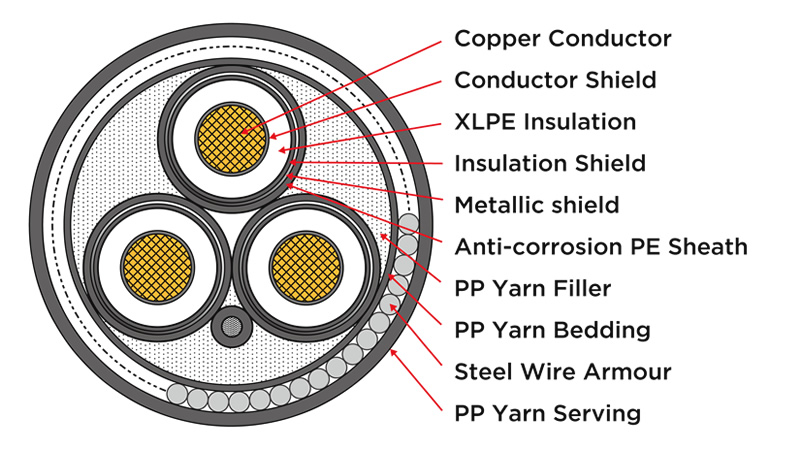

Longitudinal Watertight Conductor can limit the water migrate and minimize the repair length when cable is damaged on seabed. Semi-conductive compound or water swelling tape is applied in the interstices of copper wires of the conductor.

Construction of Watertight Conductor

Construction of Watertight Conductor

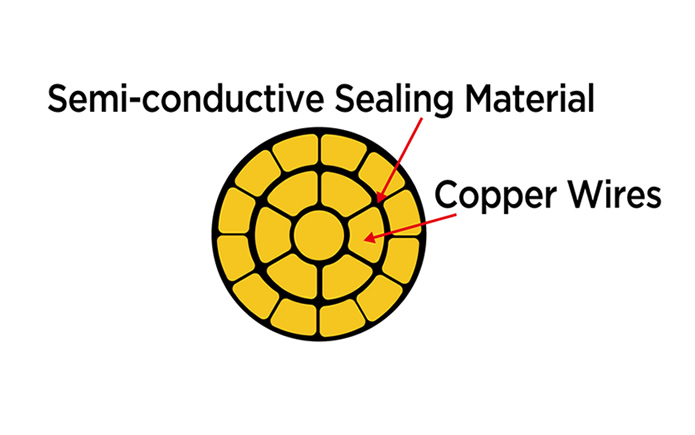

Water Migration from Damaged Point

Water Migration from Damaged Point

Especially for high voltage cables, the existence of water molecules inside the insulation leads to insulation break down in the future. The radial water barrier contributes to reducing the risk of break down caused by the inclusion of water molecule. In order to achieve radial water barrier, lead sheath is applied to high voltage submarine cables. In case certain amount of water penetrates into XLPE insulation, electric field concentrates to water molecule. Then electric conductive path will be generated and get growing. When electric conductive path connects conductor shield and insulation shield, break down occurs.

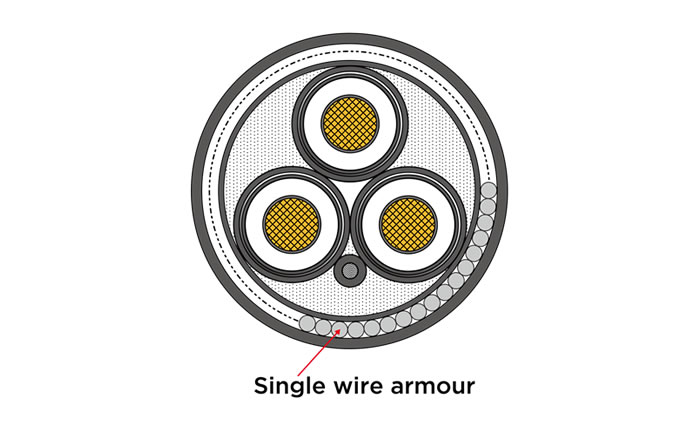

This contributes to withstand external damages and cable tension. Single, Double or Tape wire armour is applied to the outer side of the cable.

Cross Section of 3-Core Submarine Cable with Single Wire Armour

Cross Section of 3-Core Submarine Cable with Single Wire Armour

XLPE stands for Cross (X)-Linked Polyethylene. Maintenance free, environmental friendly (No risk of water pollution). Currently XLPE cables are the most often used in AC cable systems. For submarine application, formerly paper insulated cables were used mainly for EHV classes, but recently XLPE cables become the main stream up to 230 kV classes. Even for DC application, DC XLPE compound has been developed and commercial operation has started.