Projects id Formidable Social Challenges Expertise that underpins the manufacturing operations Analysis technologies to probe into root cause

Advanced Analysis Technologies Accelerate Manufacturing Mission of the Analysis Technology Research Center

Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) achieves high-sensitivity surface analysis of elements and structures of chemical species.

Integration of material analysis and CAE technologies

In January 2022, the Analysis Technology Research Center (ATRC) of the Sumitomo Electric Group will mark the 20th anniversary of its opening. Its operations date back to the 1960s, when the Test Section was set up in-house, which led to the establishment of the Analytical Characterization Center. Meanwhile, the Computer Department was set up to perform computer-based analysis. The organization was upgraded and expanded, resulting in the establishment of the CAE Research Center. The activities that led to the establishment of the Analytical Characterization Center focused on “analysis” to directly observe and evaluate objects, while the CAE Research Center focused on “analysis” to make predictions based on theoretical calculation.

Computer-aided engineering, or CAE, refers to a system to conduct a preliminary study by computer simulation to determine whether products and materials have problems in terms of performance and quality in the development, design, and manufacturing phases. It enables calculation of physical phenomena, such as the status of force applied, fluid flow, heat transfer, and electromagnetic field. It can also visualize invisible phenomena in and outside objects, such as stress, temperature, and electromagnetic field. Thus, CAE makes it possible to probe into the cause of defects, predict the strength and service life of products, and verify various designs without fabricating prototypes. Recently, CAE has been used by many manufacturers, and it has emerged as an important tool to ensure product reliability and competitiveness.

The Analytical Characterization Center and the CAE Research Center worked on a mission to offer their solutions to the entire company. They were integrated in 2002 to establish the ATRC to probe into the root cause of issues more thoroughly and extensively. According to the prospectus of establishment, the ATRC aims to “change analysis technologies.” More specifically, the ATRC’s mission is to offer solutions for probing into the root cause and solving issues related to products and to develop analysis technologies beyond simply conducting analysis. The mission also includes promotion of information sharing through horizontal deployment of findings derived in this process, thereby strengthening the foundation of the manufacturing operations of the Sumitomo Electric Group.

Technologies to “make the invisible visible”

What are the tasks of analysis? Atsushi Kimura, General Manager of the ATRC, said, “Simply put, they make the invisible visible.”

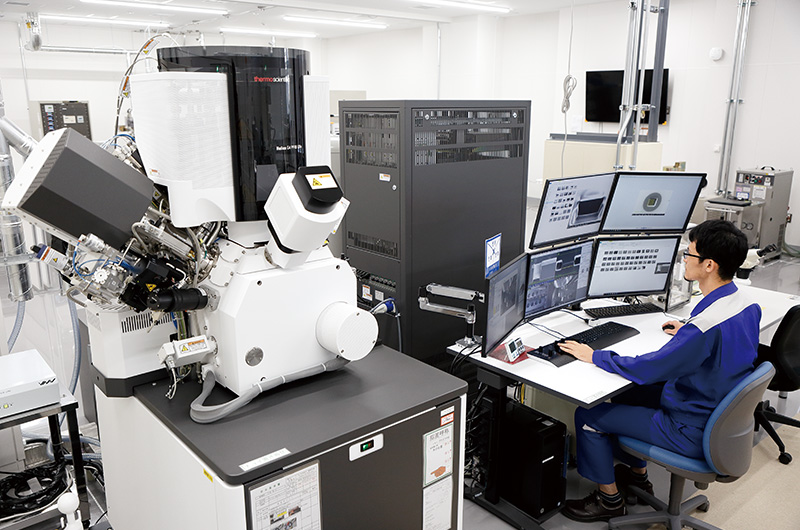

“At the ATRC, analysis means direct observation of objects, while CAE means a theoretical prediction of invisible or potential phenomena. For example, when the plating thickness of a product varies significantly, the analysis team and the CAE team collaborate to probe into the cause of defects. In analysis, electron microscopy is used to observe the plating's metallographic structure and growth process, which are invisible to the human eye. Chemical analysis is conducted to verify the composition concentration of the plating solution and ascertain whether plating solution ingredients work as designed. Meanwhile, CAE visualizes the electric field distribution when voltage is applied and the plating solution flow. We probe into the root cause of problems through such collaboration. As you see, both analysis and CAE are tools to make the invisible visible. This enables us to conduct examinations and take approaches from various aspects, spur discussions to solve issues, and come up with solutions,” said Kimura.

The ATRC handles all the products of the Sumitomo Electric Group. It operates in Osaka, Itami, and Yokohama to perform analysis of various products in the fields of automotive components, infocommunications, electronics, environment and energy, and industrial materials. The ATRC also owns a exclusive-use experimental station in a synchrotron radiation facility at the Kyushu Synchrotron Light Research Center, a public research institute in Tosu City, Saga Prefecture. Materials are irradiated with high-intensity X-rays to achieve in-depth analysis. (The details are discussed below.) In 2012, the China Analysis Technology Center was launched in Suzhou City, China, to support the printed circuit board business in particular, mainly in anticipation of the increase in demand to cope with quality issues at production sites in China.

Analysis technologies, which play a key role

in ensuring competitiveness

In the manufacturing business, analysis technologies have become increasingly important. It has emerged as a crucial factor in ensuring an advantage in the market.

“Recently, analysis requirements of customers have been more rigorous than before. To maintain our competitiveness, it is essential to ensure advanced analysis capabilities in-house. Some customers require analysis capabilities in their supplier appraisal standards. The assessment results will be notified, and will also be one of the materials for determining orders and market share. In competitive procurement by automakers, suppliers must present the reliability test results of their products. Recently, they are required to present the CAE data as well. That is, suppliers must provide evidence that reliability is ensured. It is therefore extremely important to showcase the analysis capabilities and systems of our group to customers,” said Kimura.

One of the ATRC’s strengths is that it has the equipment, technologies, and personnel to perform analysis and CAE, which are perfectly suitable for the manufacturing operations by the Sumitomo Electric Group. For example, only three private companies in Japan own the exclusive-use experimental stations in synchrotron radiation facilities, which are mentioned above. The equipment owned by the group is among the most advanced in the industry. Analysis and CAE technologies have been accumulated through many years of operations and have been passed down to date from one generation to the next. What is needed to further advance analysis technologies and improve their capabilities?

“Advancement of the information hub functionality is one of the aspects that we hope to strengthen in the future. We will deploy the findings derived from analysis and create a knowledge database of analysis. We will also enhance guidance and management to maintain the performance of the analysis equipment at production sites and improve the skills of operators. Meanwhile, it is also required to increase the efficiency of the business operations by promoting specialization of the analysis tasks and building a platform. The targets of analysis change rapidly, and analysis technologies continue to evolve. Thus, we actively promote alliances and collaboration with external organizations to harness cutting-edge technologies. We will deepen cooperation, including personnel interaction, with SPring-8, a synchrotron radiation facility of the highest performance in the world, the Japan Proton Accelerator Research Complex (J-PARC), and research institutes and universities. Through these efforts, we aim to take full advantage of cutting-edge analysis technologies to support the manufacturing operations of the Sumitomo Electric Group,” said Kimura.

General Manager of the Analysis Technology Research Center