Projects id Prestressing Steel Supports Infrastructure around the World

Optical Fibers Observe the Soundness of the Bridge Tsukidate Viaduct on a road to support the post-earthquake recovery

Tsukidate Viaduct (Photo courtesy of Kajima Corporation)

Recovery from damage of the Great East Japan Earthquake The transportation infrastructure development is in progress

The Great East Japan Earthquake in March 2011 caused devastating damage. While the damage affected a wide range of fields, the disruption of the rail, road and other transportation networks particularly had a major impact on the local communities. Roads are actually indispensable channels for emergency transportation of support staff and relief supplies, reminding us of the importance of connecting the affected areas and the inland region. A leading project for quick recovery from damage of the earthquake was the Tohoku-Chuo Expressway Soma-Fukushima Road and Sumitomo Electric supplied prestressing steel and related products for the construction of the Tsukidate Viaduct on the road.

Challenges to salt and freezing damage Efforts to extend the life of the bridge

Tsukidate Viaduct is 462 m long and one of the longest prestressed concrete bridges on Soma-Fukushima Road. The person in charge of the construction management was Mr. Yukihiko Morita from Kajima Corporation.

"One of the features required for the bridge was a long life. The location is exposed to high risks of salt and freezing damage so high durability was needed to reduce the lifecycle cost from a long-term perspective. Along with the quality of the concrete, highly durable prestressing steel strands were essential."

In response to such demand, Sumitomo Electric supplied high-corrosion-resistant prestressing steel strand that has PE coating in addition to the ordinary corrosion-resistant coating. The anchorage system supplied for the project also had specifications to prevent salt damage such as coating with epoxy film.

Monitoring of the tensile strength of prestressing steel cable

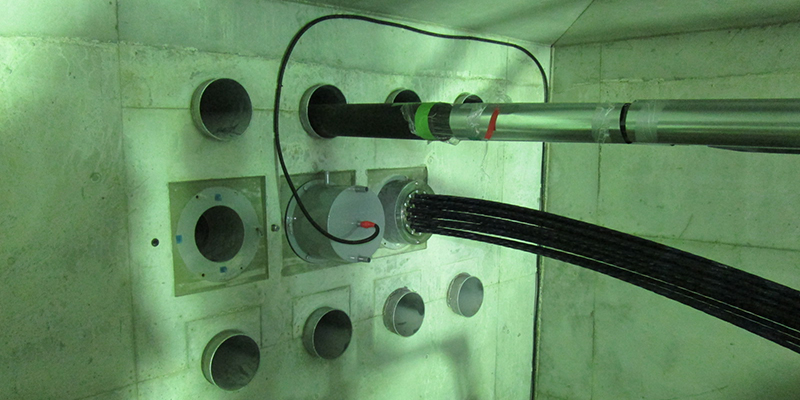

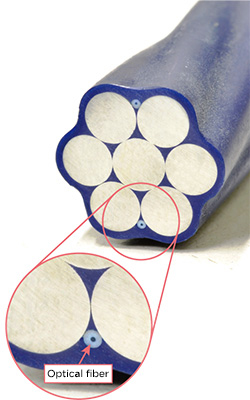

Sumitomo Electric also introduced a groundbreaking technology into the construction work, namely "optical fiber-embedded strand" in which optical fibers are incorporated into a prestressing steel and related product. This enables the measurement of the strain created on the optical fibers to assess the distribution of tension over the entire length of the prestressing steel cable, which was difficult to achieve by conventional technologies. Coated with epoxy resin, the optical fibers have no risk of being damaged during the construction work and can be used for measurement over a long term. This product was created through joint development between the three companies of Kajima Corporation, Hien Electric Industries, Ltd. and Sumitomo Electric. Mr. Naoki Sogabe from Kajima Corporation was one of the members who led the development.

"For the construction and maintenance/management of a prestressed concrete bridge like Tsukidate Viaduct, it was necessary to control the tensile strength of prestressing steel cables. To this end, we planned to realize the idea to use optical fibers for the measurement of the tensile strength, which Kajima Corporation had considered for a long time. To overcome the challenge of integrating prestressing steel strands with optical fibers, the technology of Sumitomo Electric, an expert of prestressing steel and related products, was indispensable."

Integration of prestressing steel strands with optical fibers A problem occurred on the construction site

The person in charge of the development in Sumitomo Electric was Masashi Oikawa.

"We developed a technology to incorporate optical fibers into epoxy resin and completely integrate them so that a long-life sensor function can be added while the high durability of prestressing steel strands are maintained. On the other hand, the firm coating made it extremely difficult to take out the optical fibers to be connected to measuring equipment from prestressing steel strand. At first, the coating was cut manually to take out the fibers, which took so much time that it affected the progress of the construction work."

Oikawa and other staff concentrated their knowledge accumulated through the past technological development on the solution to the problem. As a result of repetitive consideration of tools and methods, they successfully reduced the time to remove the coating and take out the optical fibers, allowing the practical use of the product.

"The management of tensile strength with optical fiber sensors is fairly groundbreaking. A future task is to make effective use of the monitoring data. We would like to work for the sophistication of the maintenance and management technology from a comprehensive perspective in cooperation with staff from Sumitomo Electric." (Mr. Sogabe mentioned above).

Furthermore, SmART Cell™ has also been applied to Tsukidate Viaduct, which is a magnetic tension sensor developed by Sumitomo Electric to measure the tensile force with pinpoint accuracy. In addition to the development and supply of prestressing steel strand and the anchorage system, an extensive line of related system products helps improve the reliability of the prestressed concrete technology.