FIBER OPTICS PRODUCTS for FTTx Solutions

Overview

Key Technology

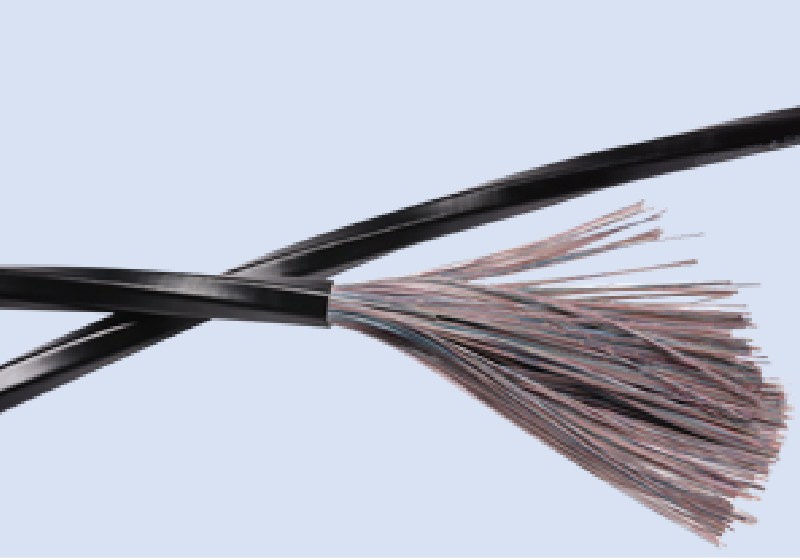

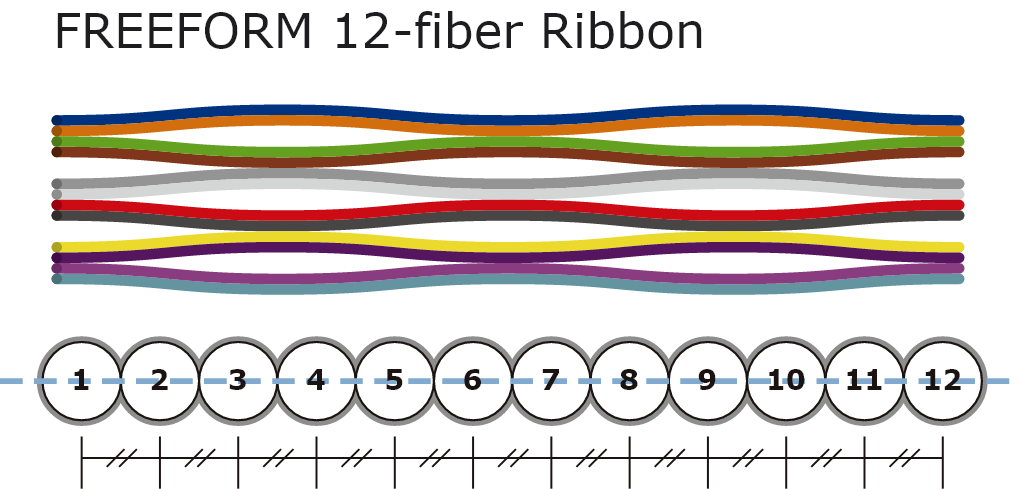

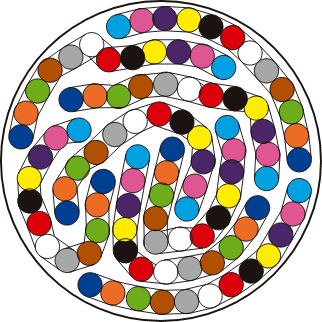

FREEFORM Ribbon™

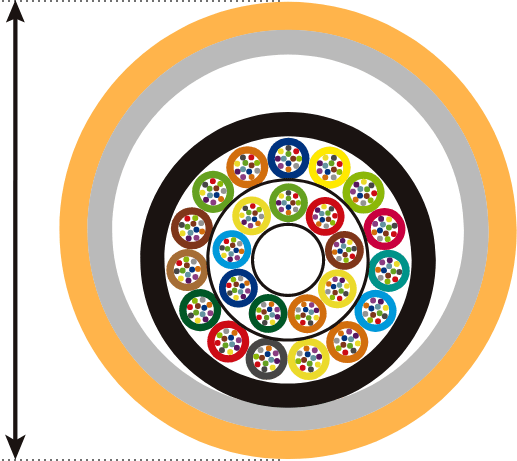

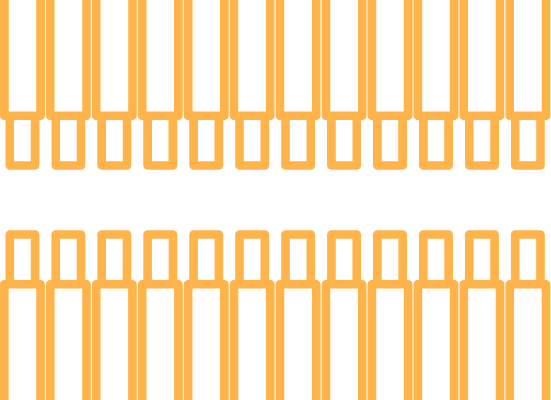

FREEFORM Ribbon™ enables dense fiber packing and smaller cable diameters, enabling higher densities in space-constrained situations. In addition, the 12-fiber ribbon “FREEFORM”, which has achieved the world’s highest level of precision, is horizontally and vertically aligned. It provides the same workability as conventional flat fiber ribbons. Therefore, FREEFORM Ribbon™ provides high workability and an optimized fusion splicing process.

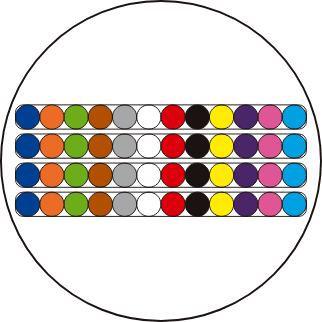

High Density

Able to pack higher fiber count compared to conventional ribbon fibers.

12-fiber

Ribbon

(48 Fibers)

FREEFORM

Ribbon™

(96 Fibers)

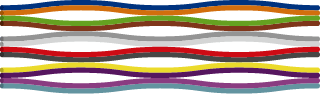

Mass Fusion Splicing

Splicing 12 fibers fusion at a time saves fusion splicing time dramatically.

80% reduction of time compared to 12 times of single splice.

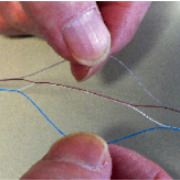

Easy Connectivity

Ribbon is simply split into single fibers.

Easy compatibility with conventional loose tube cable.

Features and Benefits

- More Fibers,

Higher Density - Quick Network

Construction - Wide Range

Application

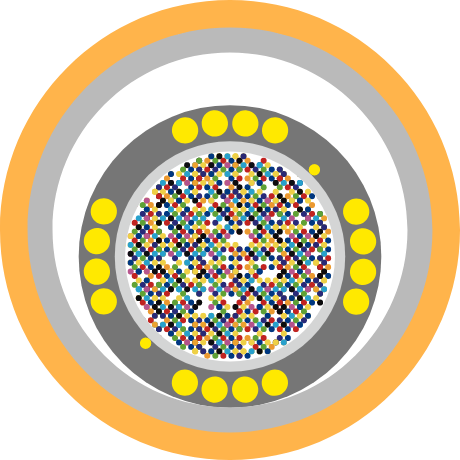

01 . More Fibers, Higher Density

High fiber count from

144 up to 864

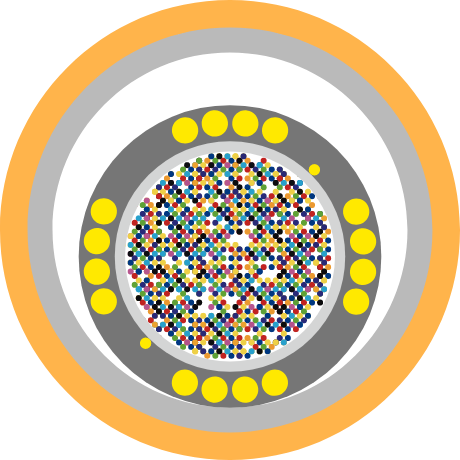

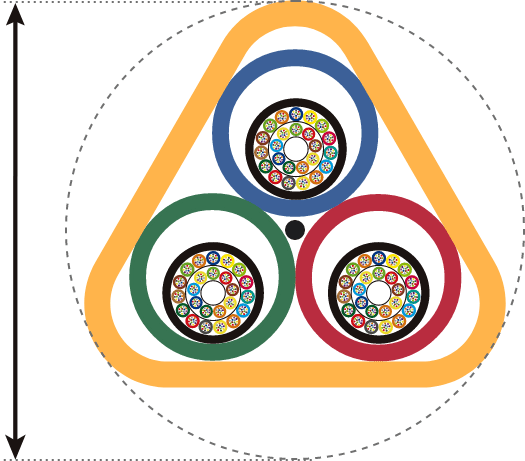

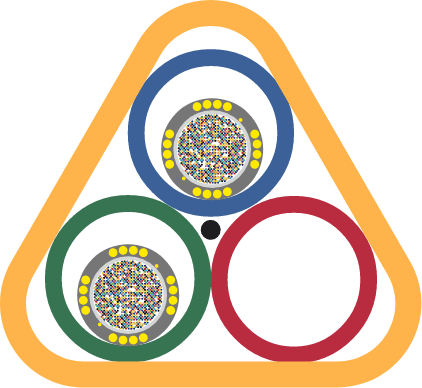

We have an innovative ultra high fiber count cables lineup from 144 up to 864. Install your fibers efficiently with future demand in mind.

Greater utilization of existing duct

The diameter of our microduct cables has been dramatically reduced.

For example, compared to a conventional 10.2mm 288-fiber microduct cable, Sumitomo’s microduct cable enables deployment of 432 fibers in the same duct space. This feature demonstrates more efficiency as the number of fibers increases. Conventional 288-fiber cables occupy three ducts to install 864 fibers, but our 432-fiber cables uses only two. Extra duct can be rented out or set aside for future expansion.

The high density packing and smaller diameter, provides a solution to maximize the utilization of existing duct.

Inn.

Diameter

15mm

(0.6 in)

288-fiber 10.2mm

1.5x more

fiber

432-fiber 10.5mm

Outer

Diameter

42mm

(1.7 in)

3×288-fiber cable = 864 fiber

1 duct

saving

2×432-fiber = 864 fiber

02 . Quick Network Construction

80% reduction of time compared to single splice

Our mass fusion splicer and ultra high density microduct cable combination brings you a dramatic working efficiency. Mass splicing 12 fiber ribbon reduces splicing time by up to 80% compared to single splice.

- 1fiber × 12splices

- 25min

80%

Reduced

- 12fiber × 1splice

- 5min

*Includes preparation time

Gel-free water blocking design

Gel-free water blocking design makes it easy to install your cables.

Avoid wasting valuable time in cleaning off gel before splicing or termination!

No hand wash

Lower costs, higher ROI

Our ultra high density microduct cable increases ROI by lower installation costs per fiber, lower duct rental fees and lower storage costs.

03 . Wide Range Application

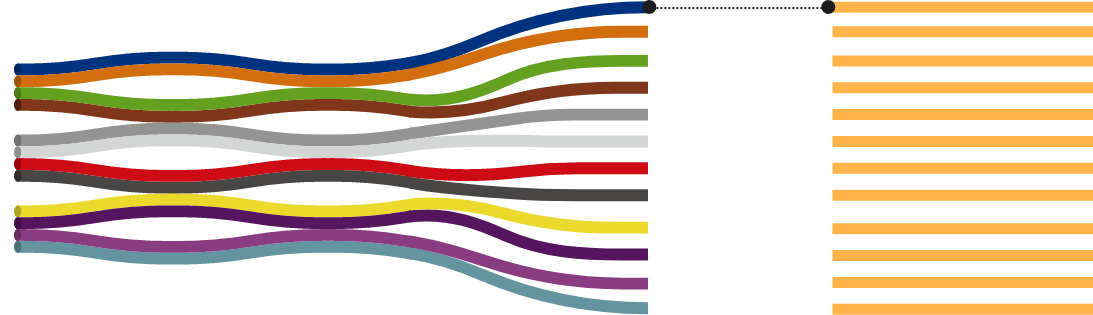

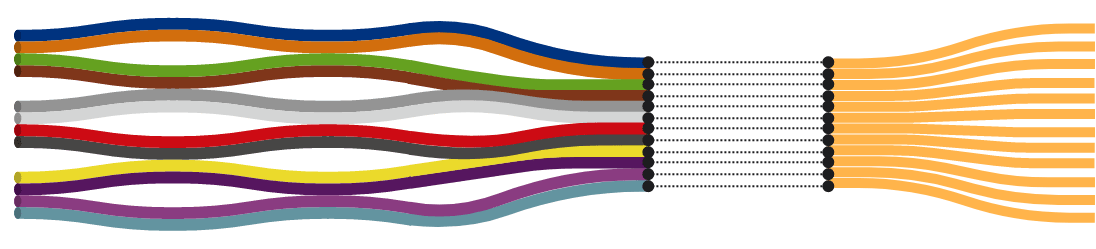

Compatibility with existing network

FREEFORM Ribbon™ can be easily split into single fibers for single splice. And also singles fibers can be ribbonised by ribboniser for mass splicing.

Just connect with your existing work(not ribbon cable) as usual.

We utilize fibers meeting ITU-T G.652.D / G.657.A1.A2 standards, perfect for any application such as FTTx, data centers and 5G infrastructure.

Easy to split and

connect with

single fibers

Able to mass fusion splice with ribbonized single fibers

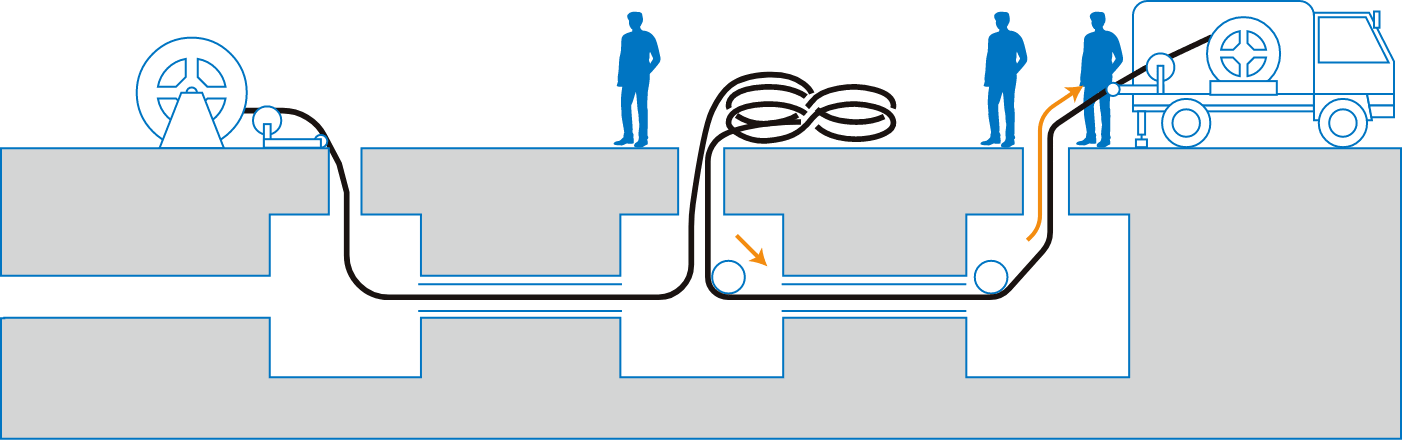

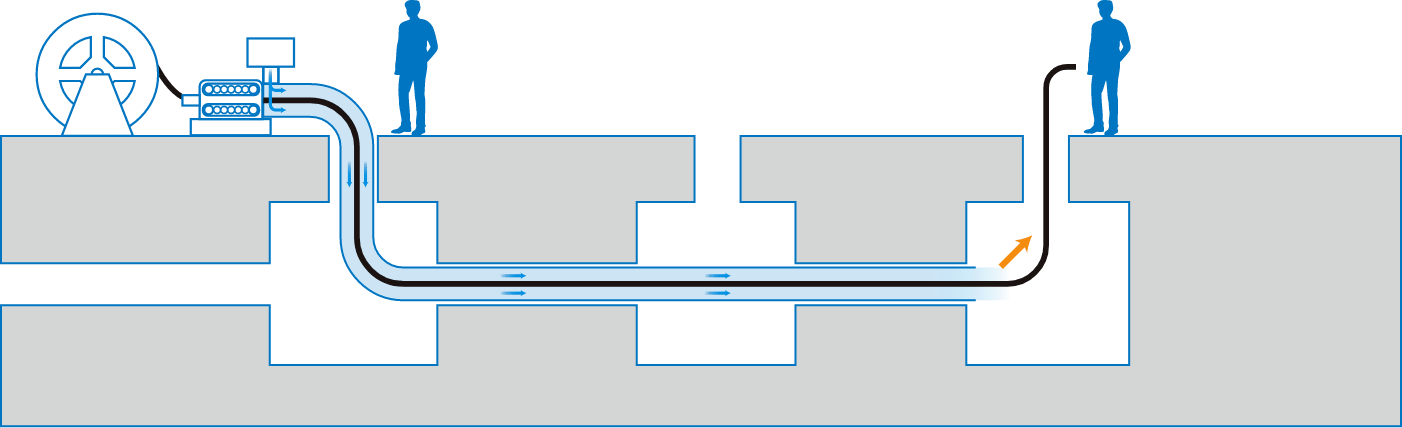

Pulling/Air-blown dual use

With innovative, lightweight and ultra low friction sheath, our microduct cables can be used not only for air-blowing but also for pulling installation.

Our fibers passing higher proof-test level of 1.5% can have higher resistance against strain for cable pulling.

Specification

200µm

| Fiber Count (No.) |

Cable Diameter (mm) |

Min. Duct Size (mm) |

Min. Bend Radius after installation |

Min. Bend Radius during installation |

Tensile strength |

|---|---|---|---|---|---|

| 144 | 7.2 | 10 | 150 | 150 | 500 |

| 192 | 7.6 | 12 | 150 | 155 | 500 |

| 288 | 9.5 | 13 | 150 | 190 | 500 |

| 432 | 10.5 | 14 | 150 | 210 | 500 |

| 864 | 13.5 | 18 | 200 | 270 | 1000 |

250µm

| Fiber Count (No.) |

Cable Diameter (mm) |

Min. Duct Size (mm) |

Min. Bend Radius after installation |

Min. Bend Radius during installation |

Tensile Strength |

|---|---|---|---|---|---|

| 144 | 8.0 | 12 | 150 | 160 | 500 |

| 192 | 8.7 | 13 | 150 | 180 | 500 |

| 288 | 10.5 | 14 | 150 | 210 | 500 |

| 432 | 12.5 | 18 | 150 | 250 | 500 |

| 864 | 14.9 | 20 | 300 | 300 | 1000 |

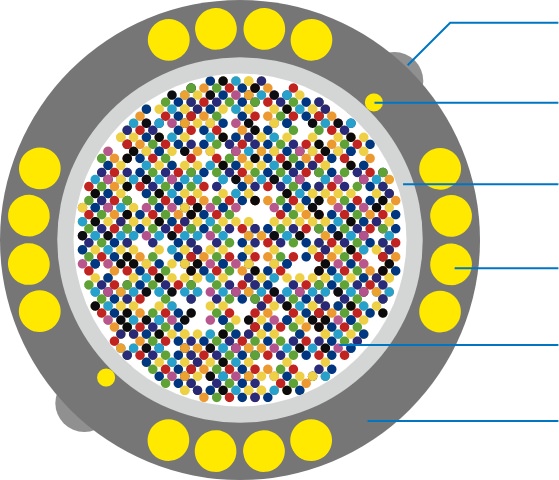

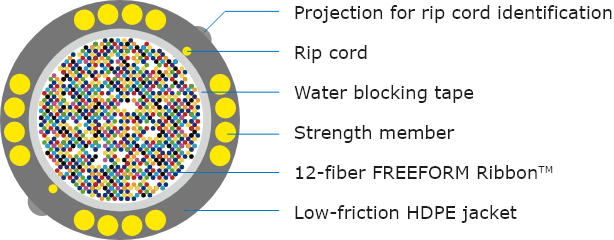

Projection for rip cord identification

Rip cord

Water blocking tape

Strength member

12-fiber FREEFORM Ribbon™

Low-friction HDPE jacket

FAQ

- Is it possible to splice 200µm coated ribbon fibers to existing 250µm ribbon fibers?

- Yes. Expand the 200µm ribbon pitch to match the pitch of a 250µm ribbon by using a pitch conversion fiber holder (Sumitomo Electric’s part No. PCH-12).

- How to splice FREEFORM 200µm ribbon fibers to FREEFORM 200µm ribbon fibers?

- There are two options. One is using the 200μm V-groove mass fusion splicer. And another is using the 250µm V-groove mass fusion splicer along with 200µm to 250µm pitch conversion fiber holder.

- How far can we blow it?

- Blowing distance directly depends on to the weight of the cable, the friction from the microduct, the pressure applied. Ask us from the “Contact us” button below, if you need further information.