Activities to Prevent Global Warming

Reduction of Greenhouse Gas Emissions

Prevention of global warming is a crucial issue for the Sumitomo Electric Group because it can also bring business opportunities while contributing to reduction of energy consumption. We will shift our focus to the introduction of initiatives into overseas establishments. As a quantitative target to be achieved in fiscal 2022, we aim to reduce overall greenhouse gas emissions from all of our establishments in Japan and overseas by 5% from the FY2017 level in the Action ECO-22V Campaign.

Initiatives by Production Units

- (1)

- enhancing energy use efficiency by improving the operation ratio of manufacturing facilities, reducing the percent defective and increasing productivity;

- (2)

- reducing fixed energy consumption for lighting, air conditioning and other utility equipment and minimizing energy consumption during non-operating hours; and

- (3)

- replacing current air conditioners, compressors and other equipment with higher efficiency units.

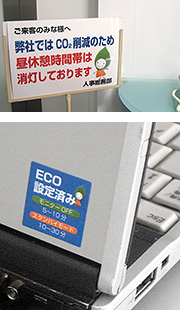

Energy Saving Activities in Offices

We have reduced GHG emissions per floor area in offices through energy saving activities. Mainly to reduce the use of electricity, we have assigned a member and a vice member of the Workplace ECO Activity Promotion Committee in Osaka and Tokyo head offices, district offices and branch offices, and promoted various efforts as follows:

- (1)

- Moderating air conditioning usage by dressing cool in summer and warm in winter.

- (2)

- Turning off all office lights during lunch break

- (3)

- Turning off lights and air conditioners in meeting rooms and toilets when not in use

- (4)

- Turning off PCs when not in use.

Logistics Units

The Sumitomo Electric Group has been making efforts to reduce environmental impact from distribution of products and materials for many years and promoted measures to reduce CO₂ and other greenhouse gas emissions and energy consumption during transportation through such efforts as improving loading efficiency, joint cargo transportation, and replacement of truck transportation by other means that have less environmental impacts such as rail and marine transportation (modal shift). Thus, we have taken the initiative in establishing an environmentally friendly logistics system. In response to revision of the Law concerning Rational Use of Energy in April 2006, which now requires all shippers to make efforts to reduce CO₂ emissions from cargo transportation, the Sumitomo Electric Group established the Green Logistics Promotion Task Committee and is working together with all domestic affiliates to promote green logistics.

Reducing Delivery-related Environmental Impacts

In addition to the known shippers with large freight volumes, which are subject to regulations, we strive to realize more environment-friendly logistics in our manufacturing affiliates in Japan by reducing per-unit CO₂ emissions through the promotion of modal shift and improvement in the truck loading efficiency.

Initiative to Promote Modal Shift

Since fiscal 2002, we have been promoting modal shift mainly in the case of large-volume freight within our group. In addition, we are actively promoting round-trip railway transportation using large containers in partnership with companies outside our group.

Sumitomo Electric is actively using railway container services for the transportation of copper wire rod from Osaka works to Miyagi and Tochigi. In recognition of the fact that 50.8% of our freight land transportation covering 500 km or more in fiscal 2011 was by rail, we acquired certification as a company engaged in the initiatives of Eco Rail Mark from the Railway Freight Association in February 2013.

Cooperation with Companies in and outside the Industry

We have been promoting modal shift in partnership with Furukawa Electric Co., Ltd. from October 2008,under the initiative of the Logistics Committee of the Japanese Electric Wire & Cable Makers' Association, as the first case of a "Solution Team on Modal Shift (composed of shippers, forwarding companies and Japan Freight Railway Company)" proposed by the Japanese Ministry of Land, Infrastructure, Transport and Tourism.

Sumitomo Electric is currying copper wire rods from Osaka works to Utsunomiya, and Furukawa Electric is currying copper products from Nikko to Amagasaki on the return trip using two 31-ft containers.

In fiscal 2017, with this effot of modal shift, CO₂ emissions from Sumitomo Electric could be reduced by about 79 tons a year.

Increasing Truck Loading Efficiency

Sumitomo Electric has introduced “Haiso-desu”[*] truck delivery planning system software developed and marketed by Sumitomo Electric System Solutions Co., Ltd, a member company of the Sumitomo Electric Group, to increase truck loading and circulation efficiencies, thereby reducing the number of trucks used and reducing CO₂ emissions accordingly.

*“Haiso-desu” is a registered trademark of Sumitomo Electric Industries, Ltd.

227 KB)

227 KB)